- Cyprus

- Almware Ltd.

- +357 22 030575

- info@duotek.dev

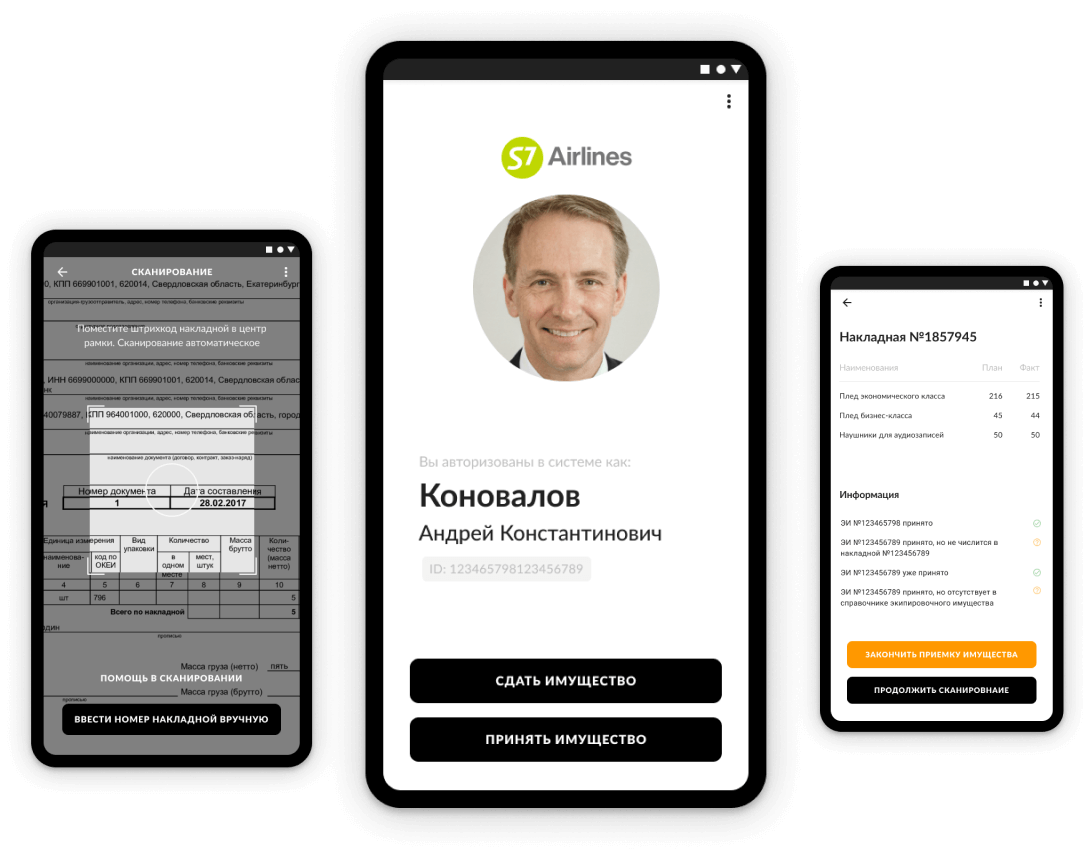

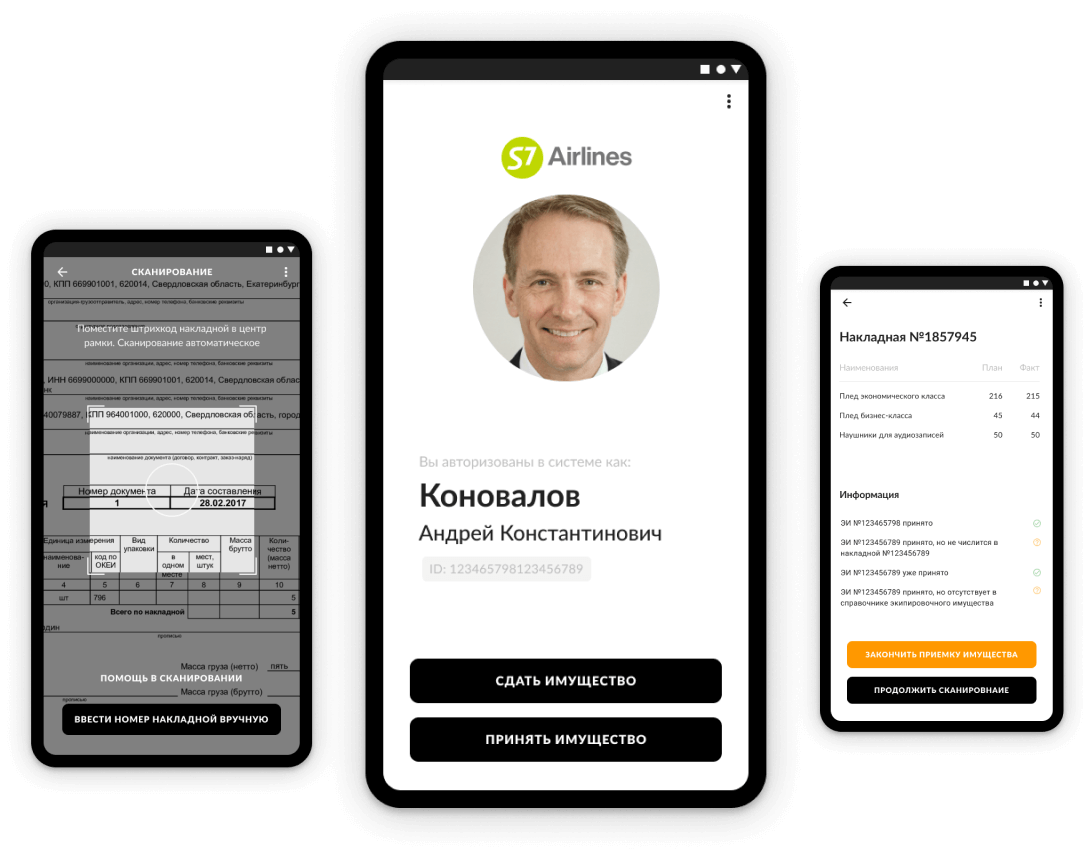

Flight attendant's mobile terminal for automated acceptance and handing over of equipment on board

- What We Did

- Design

- Mobile Development

- Integration with MS Dynamics

- Deployment

- Technologies

- RFID

- Kotlin

- Microsoft Dynamics NAV

- Team

- Project Manager

- George Poplavsky

- Software Design

- Dmitry Yurkin

- Developers

- Andrey Verkeev

- Dmitry Kuzmin

- QA

- Maria Suhorukova

- Margarita Bakashova

About the Project

We designed and developed a mobile application for portable warehouse terminals with RFID tag scanners. The app swiftly identifies the number of items being boarded before a flight and returned after a flight, automatically updating the company's ERP system.

Challange

The airline faced challenges tracking items, such as blankets, fire extinguishers, or other inventory essential for passenger service and flight organization. Items went missing when transferred from the warehouse to the aircraft and vice versa. The company couldn’t pinpoint at which stage the loss occurred: during warehouse packaging, in-flight, or upon returning from the flight.

There was no oversight of the number of items when transferring onboard and off due to the inability to quickly tally them.

The company sought automation to achieve the following goals:

- Relieve flight attendants and dispatchers from routine tasks.

- Enhance data collection accuracy.

- Automatically transfer data into the airline's ERP system (Microsoft Dynamics NAV).

Objective

Previously, quantities were calculated using stationary portals with metal detectors. For instance, dispatchers would collect hundreds of blankets with embedded RFID tags into large bags and pass them through these portals. This process was often repeated, yet it still couldn’t guarantee complete counting accuracy. No recounting occurred when bags were received on board.

The Airline Company opted to discard the costly and complex portal technology, replacing it with portable warehouse terminals with built-in RFID tag scanners. This necessitated:

- Creating a mobile app for handheld terminals and industrial tablets.

- Integrating the app with the company's ERP system.

- Ensuring offline functionality.

Solution

We engineered, developed, and implemented a mobile application for handheld terminals (Chainway C72-U1T1) and industrial tablets (RFID UHF IQTAB8). This allows dispatchers and flight attendants to quickly recount items on board. The application is directly integrated with the company's ERP system.

How does the application track the movement of items?

Each dispatcher is equipped with a handheld terminal that features an RFID scanner and the installed mobile application. When aimed at the bags containing items, the terminal reads the number of items in the load and transmits this data to the company's ERP system.

Inspections are carried out at two points:

The dispatcher delivers the items onboard and selects the attending flight attendant from the app's database. They then point the scanner at the loaded items. The application automatically generates a document detailing the number of items taken onboard and forwards it to the airline's ERP system. If there is no internet connection, it saves to a local database.

The dispatcher, using the application, selects the attending flight attendant for handover (or uses the "Flight Attendant Absent" function if the crew has already left the aircraft). They either scan the document's barcode or manually input its number. Then, the dispatcher identifies the quantity of items by scanning storage locations. The data is transmitted to the ERP, and the dispatcher transports the items to the warehouse.

By monitoring changes in the number of trade and material values during transfers, the airline can pinpoint at which stage items are going missing and in what quantities.

The application implements essential functionalities for a dispatcher's complete operational cycle:

- Dispatcher and flight attendant authorization.

- Handover of property.

- Acceptance of property.

- Scan documents via barcode or manual entry of the document number.

- Update of the mobile app's local database.

- Information on the last synchronization date with the airline's ERP database.

Outcome

Automated Items Tracking Onboard

The airline now has a mobile application for automated tracking of items from the warehouse to the aircraft and back. Data is automatically fed into the ERP, enabling the company to precisely monitor the movement of their property.

Enhanced Counting Accuracy

Upon deploying the application, we conducted on-site warehouse testing and found that handheld scanners provide a much more accurate count of RFID tags compared to stationary portals. This superior accuracy is achieved due to the scanner's targeted action and the ability to adjust its antenna's power. By setting the appropriate scanning zone, interference from unrelated tags in the warehouse is eliminated, yielding the most accurate results.

Scalable Solution

Initially, the application was set up for the pilot project to track blankets. By adding RFID tag numbers of other items into the app's database, the company can leverage it to track any inventory. There's no limit to the number of users that the application can accommodate.

Additional Features

Native Mobile Application for Industrial Devices

For the mobile application development, we chose Kotlin – a modern language for native development for Android devices. The language's inherent libraries to interface with the device's RFID scanner significantly accelerated our development process, taking only 3 months to complete.

Offline Functionality

There are many zones in an airport where mobile connectivity is unavailable. To address this, we implemented a local database within the application. When the internet connection is restored, the application automatically syncs the local database with the ERP system. Importantly, it doesn't send all the data but only the newly recorded differences.

Direct ERP Integration

The server side of the application is directly integrated with the ERP. This approach not only reduced the development timeline but also eliminated the need to allocate resources for maintaining and securing an intermediary server.

See Also